In a groundbreaking development, the German Fraunhofer Institute for Solar Energy Systems, the French company Soitec, and the Helmholtz Research Center in Berlin have set a new world record by achieving a photovoltaic conversion efficiency of 44.7% with four-junction solar cells under a light concentration of 297. This achievement marks a significant step forward in solar technology, promising to lower costs and bring us closer to solar cells with over 50% efficiency.

Earlier this year, in May, the same group of institutions, along with scientists from the CEA-Leti laboratory in France, had already reached an efficiency of 43.6% at a concentration of 319. Building on that success, researchers refined their techniques, optimized materials, and conducted in-depth studies to push the limits further, ultimately reaching the current milestone.

These high-efficiency cells are primarily used in concentrating photovoltaic (CPV) systems. CPV technology uses optical elements like lenses or mirrors to focus sunlight onto small, highly efficient solar cells, making it one of the most promising third-generation solar technologies. It offers the potential for higher efficiency and lower material usage compared to traditional photovoltaics.

The four-junction solar cell is composed of different III-V semiconductor materials—such as gallium, indium, nitrogen, and phosphorus—stacked in layers. Each subcell is designed to capture a specific portion of the solar spectrum, allowing the entire cell to convert a broader range of light into electricity more efficiently.

Frank Demers, head of R&D at the Fraunhofer Institute, highlighted the long-term efforts behind this breakthrough. “After years of research, we’ve made significant progress in both material development and structural optimization,†he said. “A key innovation was the ‘wafer bonding’ technique, which allows us to combine semiconductor crystals in a precise way, rather than just stacking them. This enables us to create the most efficient solar cell possible.â€

Andrei Jacqueliman, CEO of Soitec, expressed optimism about the future. “In just four months, the efficiency record has jumped by 1%. This shows the huge potential of four-junction solar cells. I believe we’re on the verge of breaking the 50% efficiency barrier soon.â€

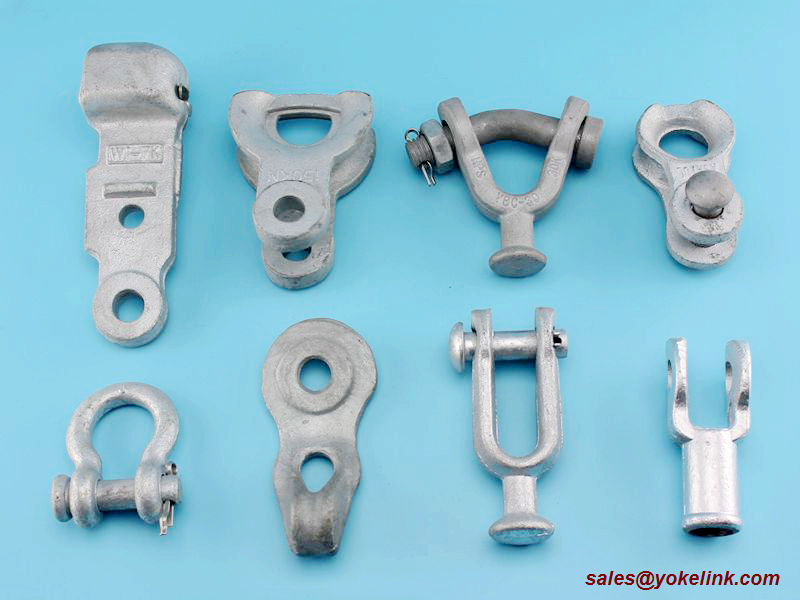

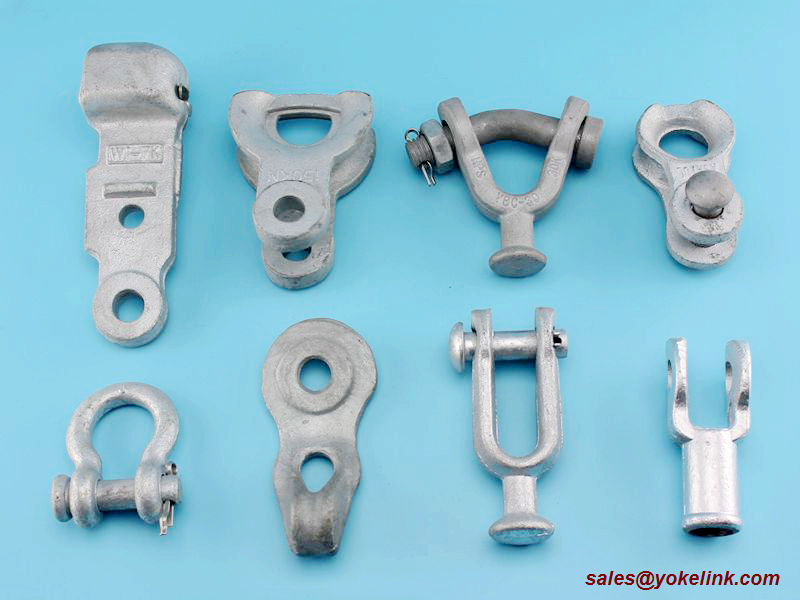

Transmission Hardware Fitting

Transmission hardware fittings are components used in the construction and maintenance of transmission lines for electricity or telecommunications. These fittings are designed to connect, support, and secure the different parts of the transmission line, ensuring proper functioning and reliability.

Some common types of transmission hardware fittings include:

Suspension Clamps: Used to hang the conductors from the transmission towers, providing support and preventing sagging.

Dead-end Clamps: Used to terminate the conductors at the ends of the transmission line, providing support and preventing them from slipping.

Splice Sleeves: Used to join two conductors together, ensuring a secure and conductive connection.

Insulators: Used to electrically isolate the conductors from the transmission towers, preventing electrical leakage and ensuring proper insulation.

Guy Wire Fittings: Used to secure and stabilize the transmission towers, preventing them from swaying or collapsing.

Connectors: Used to connect different components of the transmission line, such as conductors, insulators, and fittings, ensuring a secure and reliable connection.

Yokelink supply a full line of Tower hardwares, , provide part number to get a quote on these products, leave your message, or send us an email to get answers for your questions or product you needed.

Socket Eyes are used for connecting conductor clamping devices to ball and socket type insulators. Made by malleable iron, hot dip galvanized to meet ASTM A153 specification.

Ball Eyes are used to attach ball and socket insulators to other associated hardware. Hot dip galvanized to meet ASTM A153 specification.

Thimble Cleivs are used for attaching guy to pole eye plate. Hot dip galvanized to meet ASTM A153 specification.

Turnbuckles are used as adjustable extension links to maintain proper tower clearance on assemblies at tower end.

Strain Clamp used for distribution and transmission line construction with all aluminum ACSR, or aluminum alloy conductor.

Transmission Hardware Fitting, Socket,Ball eye, Hot line, Chain Link, Turnbuckle, Suspension, Strain, Yoke plate,malleable iron,hardware,tower,links

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com