Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Introduction

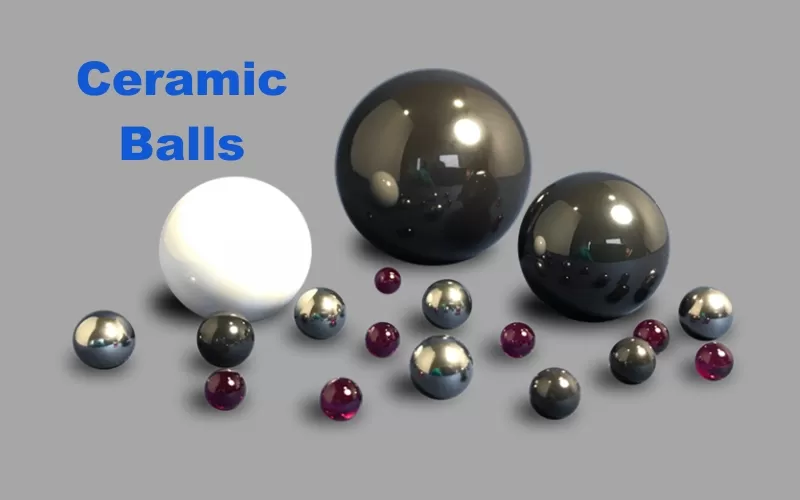

Ceramic balls play a crucial role in various industries due to their unique properties and characteristics. These ceramic balls are used in applications that demand durability and precision, such as bearings, grinding media, and valve components. This article aims to provide a comprehensive understanding of ceramic balls, their types, manufacturing processes, and advantages over traditional materials such as steel. Through in-depth research, we will help you optimize your application using the most suitable ceramic balls.

What Are Ceramic Balls?

Ceramic balls are spherical rolling elements made from advanced ceramic materials that are processed and sintered at high temperatures to achieve superior mechanical properties. Their unique combination of hardness, low weight, and chemical inertness allows for their use in a variety of demanding industrial applications.

Different Types Of Ceramic Balls

Ceramic balls are manufactured from a variety of ceramic materials, each offering unique properties and benefits suited to specific applications. Here are some common types:

✯ Alumina Ceramic Balls

- Alumina ceramic balls are primarily used in processing equipment to improve grinding efficiency, in chemical pumps, and valves, and as bearings in environments where high temperature and corrosion resistance are necessary.

Advantages:

- High-Temperature Resistance: Can withstand up to 1750°C.

- Corrosion Resistance: Excellent resistance to acids and alkalis.

- Cost-Effective: Less expensive compared to other ceramic materials, making them a popular choice for bulk industrial applications.

✯ Zirconia Ceramic Balls

- They find applications in high-precision milling and grinding processes. Zirconia balls are also used in pumps, valves, and in biomedical applications such as hip and joint replacements.

Advantages:

- High Strength and Toughness: Exceptional fracture toughness and high strength which make them resistant to cracking.

- Wear Resistance: Extremely resistant to wear and tear, useful in grinding operations.

Low Thermal - Conductivity: Suitable for applications with minimal thermal expansion requirements.

✯ Silicon Nitride Ceramic Balls

- These balls are commonly used in high-speed bearings, automotive components, and aerospace applications.

Advantages:

- Lightweight:

Low porosity clay bricks are made of low aluminum mullite as the main raw material, formed by high pressure molding and high temperature sintering. The main mineral composition is mullite phase, the product has excellent high temperature physical properties and chemical erosion resistance.

Low porosity clay brick stability is good, the degree of erosion does not occur sudden change, than ordinary clay brick life increased by 2 to 3 times. Thermal conductivity, specific heat and solubility, respectively, than ordinary clay bricks 2 times higher than 10% and 40%, heat storage capacity than ordinary clay bricks 50% to 60% higher than the thermal efficiency of the kiln can be improved.

Low porosity clay bricks are characterized by:

1. Low porosity, 13 to 15%;

2. Load softening temperature is high for about 1472 ℃;

3. High compressive strength at room temperature, generally about 100MPa;

4. Good volume stability at high temperature and good abrasion resistance;

5. good resistance to infiltration and erosion.

Low porosity clay brick as a good clay refractory brick products, so often used in chemical erosion, temperature fluctuations in the environment, such as steel, glass, chemical industry. The effect is quite obvious in the use of glass hot room and the use of iron water tank.Suitable for Plugging Oven Holes,Clogging Refractory Clay Bricks,Clogging Refractory Clay Brick

Huixian Xinwei Refractories Co. , https://www.xinweirefractory.com