Categories

-

Adapter Sleeves (9)

-

Ball Bearings (11)

-

Ball Screw Bearings (2)

-

Ceramic Bearings (27)

-

Pillow Block Bearings (4)

-

Plain Bearings (32)

-

Roller Bearings (12)

-

Slewing Bearings (43)

-

Sliding Block (3)

-

Stainless Steel Bearings (27)

-

Super Precision Bearings (6)

-

Thin Section Bearings (9)

-

Track Rollers (4)

-

Universal Joints (1)

Introduction

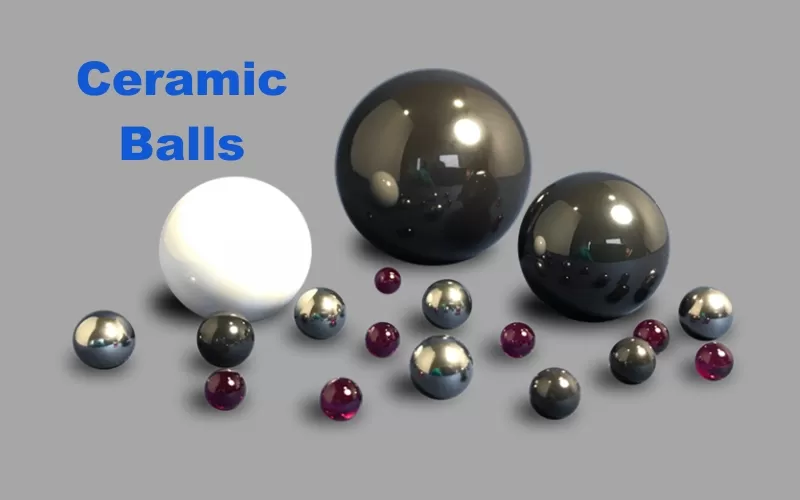

Ceramic balls play a crucial role in numerous industries because of their unique properties and characteristics. These ceramic balls are widely used in applications that demand durability and precision, such as bearings, grinding media, and valve components. This article aims to provide a comprehensive understanding of ceramic balls, their types, manufacturing processes, and advantages over traditional materials like steel. Through in-depth research, we aim to help you optimize your application using the most suitable ceramic balls.

What Are Ceramic Balls?

Ceramic balls are spherical rolling elements made from advanced ceramic materials that are processed and sintered at high temperatures to achieve superior mechanical properties. Their unique combination of hardness, low weight, and chemical inertness makes them ideal for use in demanding industrial applications.

Different Types Of Ceramic Balls

Ceramic balls are manufactured from a variety of ceramic materials, each offering unique properties and benefits tailored to specific applications. Here are some common types:

✯ Alumina Ceramic Balls

- Alumina ceramic balls are predominantly used in processing equipment to improve grinding efficiency, in chemical pumps, and valves, and as bearings in environments where high temperature and corrosion resistance are necessary.

Advantages:

- High-Temperature Resistance: Can withstand up to 1750°C.

- Corrosion Resistance: Excellent resistance to acids and alkalis.

- Cost-Effective: Less expensive compared to other ceramic materials, making them a popular choice for bulk industrial applications.

✯ Zirconia Ceramic Balls

- They are used in high-precision milling and grinding processes. Zirconia balls are also employed in pumps, valves, and in biomedical applications such as hip and joint replacements.

Advantages:

- High Strength and Toughness: Exceptional fracture toughness and high strength, making them resistant to cracking.

- Wear Resistance: Extremely resistant to wear and tear, ideal for grinding operations.

- Low Thermal Conductivity: Suitable for applications with minimal thermal expansion requirements.

✯ Silicon Nitride Ceramic Balls

- These balls are commonly used in high-speed bearings, automotive components, and aerospace applications.

Advantages:

- Lightweight: Lower density than other ceramic materials, reducing centrifugal force in high-speed applications.Refractory Anchor Brick

Refractory anchoring brick refers to have a specific shape in the industrial kiln shell or support the lining of the steel structure installed, and buried in the refractory lining of its anchoring and linking role of clay, high alumina and other refractory bricks. It has the characteristics of high strength, good resistance to scouring and high resistance to spalling.

Anchor brick for heating furnace,Coal chemical kiln anchoring bricks,Refractory anchoring bricks for heating furnac

Huixian Xinwei Refractories Co. , https://www.xinweirefractory.com